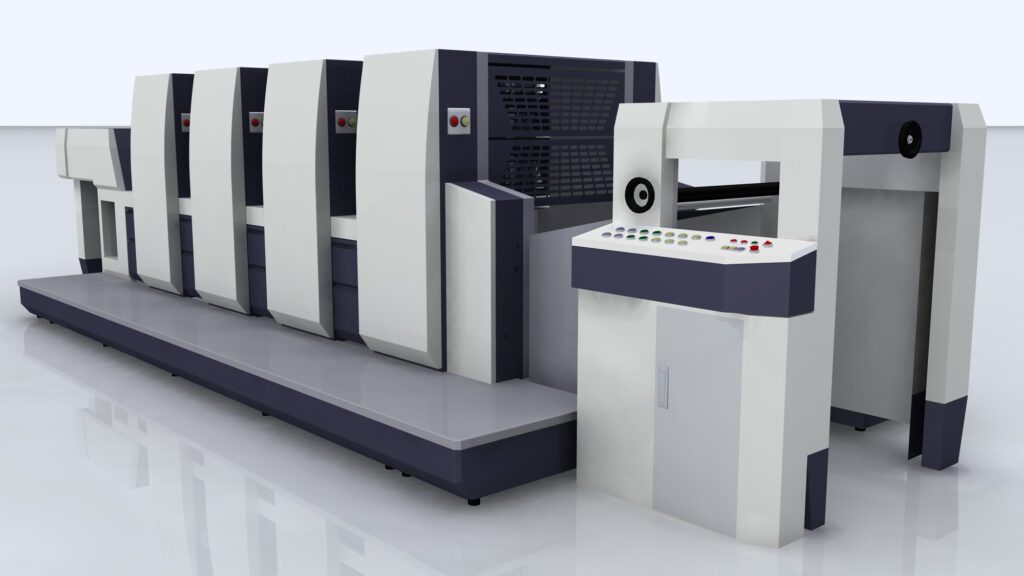

ES-4-660/740 Four Color Offset Printer

TECHNICAL INFORMAITON

- Main Technical Parameters:

| Model | ES-4-740 | ES-4-660 |

| Max. Speed | 12000s/h | 12000s/h |

| Max. Paper Size | 540×740mm | 540×660mm |

| Min. Paper Size | 273×393mm | 273×393mm |

| Paper Sheet Thickness | 0.06-0.6mm | 0.06-0.6mm |

| Max. Printing Area | 528×730mm | 528×650mm |

| Plate Size | 677×755×0.3mm | 677×675×0.3mm |

| Blanket Size | 740×760×1.9mm | 740×680×1.9mm |

| Max. Feeder Pile Height | 940mm | 940mm |

| Max. Delivery Pile Height | 780mm | 780mm |

| Machine Overall Dimension

(LxWxH) |

7380×2550×1950mm | 7380×2470×1950mm |

| Total Power | 23kw,380V,50Hz | 23kw,380V,50Hz |

| Machine Gross Weight | 19700kg | 18700kg |

According to the development of the printing market, a new generation of multi-color offset printing machine built by a number of national patent technologies is adopted, which adopts automatic pneumatic clamping system, automatic three-axis adjustment system controlled by DC permanent magnet, and precise automatic pressure regulating system. With the bus electronic control system of Mitsubishi CC-LINK communication method, it perfectly displays the characteristics of smart, intelligent and high efficiency of the heavy-duty printing machine. The stainless steel spray embossing and plate cylinder greatly extend the life of the machine. CIP4 can be used to form a digital workflow with prepress CTP and postpress, and to preset the ink color, which greatly reduces the printing factories ‘ experience for printing technicians. Under certain conditions, the operating conditions and various parameter changes of the printing press can be monitored and controlled by INTERNET, and the popular UV printing, glazing and other printing processes as well as the automatic blanket washing and the ink roller can be conveniently installed. Increased scalability of product features

1.The semi APC (Automatic Plate Changer) shortens the make-ready time.

2.To preset paper thickness when printing different kinds of paper. To adjust printing pressure in

every unit automatically, quickly and synchronously.

3.With non-stop feeder, piles are changed at production speed. It saves a great deal of time when

running thick paper and long version work offline.

4.It is equipped with CC-LINK technological bus module from Mitsubishi.

5.Double-diameter impression cylinder and transfer drum can reduce the times of sheet take-over

between print units.

6.The plate cylinder can be adjusted in the circumferential direction, lateral direction and diagonal

direction.

7.There are five rollers on the plate cylinder. There is an intermediate roller in alcoholic damping

system, which can eliminate the “ghost” image, achieve the quick ink-water balance and

reducepaper consumption.

8.There are 23 zones in split (staggered) ductor.

Standard equipment:

| No. | Standard equipment | Remarks |

| 1 | Ink remote control(optional) | |

| 2 | Alcohol dampening | |

| 3 | Bearer by bearer | |

| 4 | Double-diameter impression cylinder and transfer cylinder | |

| 5 | Special treatment on the surface of impression cylinder | |

| 6 | Special treatment on the surface of plate cylinder | |

| 7 | Semi-automatic clamp bar | |

| 8 | Register in axial and circumferential direction | |

| 9 | Cocking | |

| 10 | Automatic pressure adjustment | |

| 11 | Pneumatic impression on-off | |

| 12 | Swing-down gripper system | |

| 13 | Swing-down front lay | |

| 14 | Electric powder sprayer | |

| 15 | Lubrication like shower, partial thick lubrication | |

| 16 | Non-stop delivery | |

| Ancillary Equipment: | ||

| 17 | Photoelectric puncher (Plate can be bend) | |

| 18 | Air pump | |

| 19 | Air compressor | |

| 20 | Dampening rollers | |

| 21 | Vacuum feeder | |

| 22 | Ultrasonic double sheet detector | |

| Package: | ||

| 1 | Wooden fumigation | |

| 2 | Manual instruction, Packing list, spare parts book | |

Description:

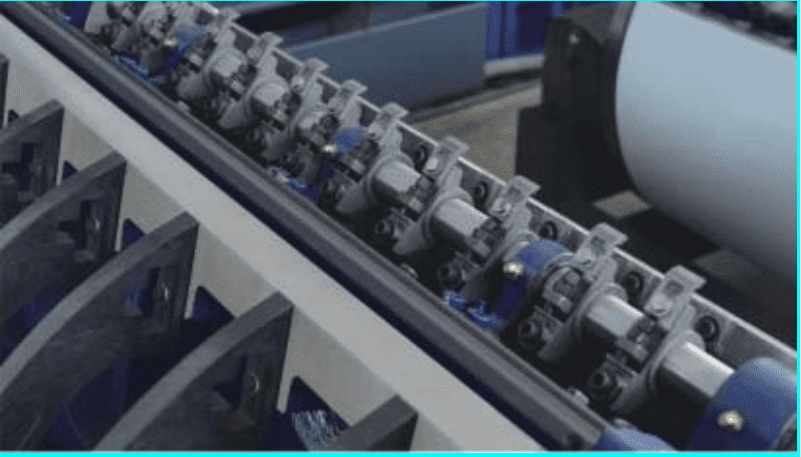

Feeder

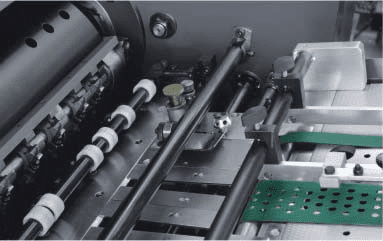

* Conjugated cam. Forwarding mechanism controlled by linear guide rail makes machine speed faster and more stable.

* Rotary valve with patent can clean paper dust automatically and reduce the fault.

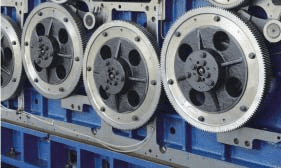

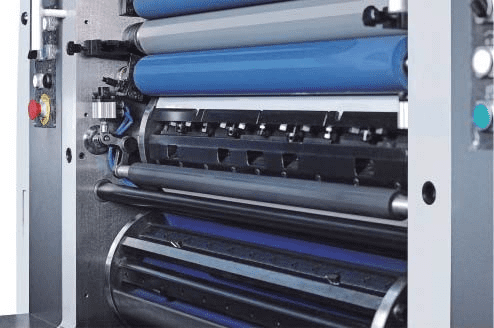

Printing Units

* Both of frame and base are integral casting.

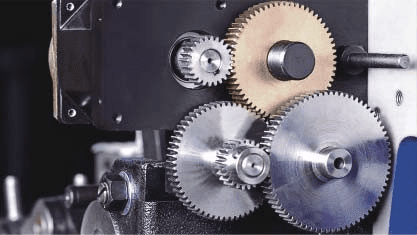

* High frequency quenching of gears guarantee transmission accuracy.

* Helical gears, high overlap coefficient and low noise

Accurate grippers

* After checkered high strength steel pads had been quenched, their life will be longer and replacement will be more conveniently.

* Wear-resistant soft pads ensure stability of paper handover and precision of paper transmission.

* High precision needle roller bearings and opening bearings improve stability of gripper system.

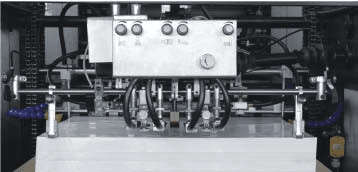

Automatic device for adjusting paper thickness

* It is equipped with gear driven. Distance between cylinders can be given some feedbacks to screen by potentiometer automatically.

* Permanent magnetic generator driven can ensure stability of printing pressure, because of large torsion and strong self-lock.

* It is easier and more convenient to input paper thickness on the screen directly.

Vacuum suction feeder table

* Imported air pump with large volume

* It is suitable for all paper in any types or size automatically, so as to change paper format more quickly and more easily.

* Ultrasonic double-sheet detector can protect cylinders better.

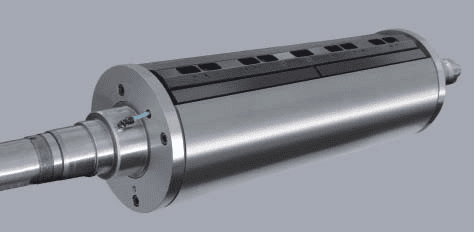

Cylinders

* The surface on the impression cylinders and plate cylinders are sprayed stainless steel so as to prolong press life better.

* Dynamic balance design can reduce vibration during printing.

Pneumatic clamp bar, Change plate without tools

* Tension of clamp bar is controlled by imported hoses and disc springs, so that it is more flexible for operation.

* Corners of cylinders are controlled by high precision encoder. Plates will be installed and dismounted by program automatically. Thus it can meet the long version and short version edition of the printing business needs.

* The tail of clamp bar is separated, so that it can help paper more smooth.

Console

* The press memory or job memory card (disk) can save the current job. Changes and settings made to the current job are transferred to the press. While in printing mode, you can enter the presetting values for next job into the press memory or stored to a disk.

* CIP3/CIP4

Ink amount control console (Optional)

* Every ink key in every unit can be set by console.

* Ink amount can be displayed in digital and can be saved.

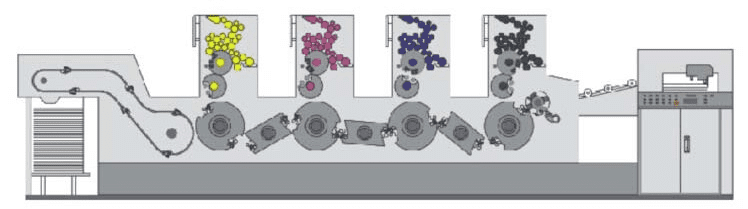

Structure Diagram

Features:

- The semiAPC (Automatic Plate Changer) shortens the make-ready time.

- Topreset paper thickness when printing different kinds of paper. To adjust printing pressure in every unit automatically, quickly and synchronously.

- With non-stopfeeder, piles are changed at production speed. It saves a great deal of time when running thick paper and long version work offline.

- It is equippedwith CC-LINK technological bus module from Mitsubishi.

- Double-diameterimpression cylinder and transfer drum can reduce the times of sheet take-over between print units.

- The plate cylindercan be adjusted in the circumferential direction, lateral direction and diagonal direction.

- Thereare five rollers on the plate cylinder. There is an intermediate roller in alcoholic damping system, which can eliminate the “ghost” image, achieve the quick ink-water balance and reduce paper consumption.